First off is the layout was designed to be movable, but not necessarily portable. What I mean by that is the layout was design to move but it is not easy. I have done some Free-mo modules in the past and the point of any modules is that you can take it to and from the site that the meeting is held. This layout is designed to broken into sections, but the sections are 3'x5' and require two people to move them. So they can move with me when the Air Force decides to move me every 4 years but I will not be breaking this thing down to take to conventions any time soon.

The nice thing about moving with the Air Force is that they will provide a moving company to move you things from location to location. So not having to worry about how to get them across the county i could focus on how to make sure they made it in one piece.

My idea was to make two boxes out of the four layout sections, by putting the tops of two layout facing each other I knew that the track would be protected. These two boxes then needed to be protected on all exposed sides to ensure the movers couldn't damage anything.

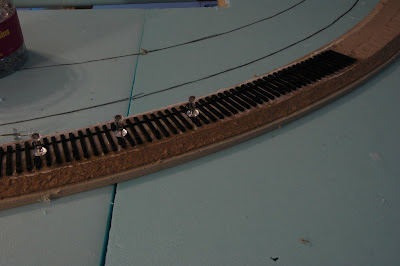

I wanted to make sure that all sides were protected, to do this I cut strips of 1/2" plywood into widths of 16". This width was calculated by how close I could get the two sections together with some between tracks. Look below to see an example on the gap between the sections

My other big concern was the underside of the layout which has all the wires and switch machines. You can see all of those things below.

To protect the underside I bought some of those 1/2" plywood precut sections from Home Depot and attached it to the legs. This both protected the underside and kept the legs locked in place.

The final product was very solid and was able to protect my layout in the move across country with no damage. Below are some different views of the final product.

I was very proud of the job I did when I was complemented by the movers on the professional job I did!

Now that we are move the layout is up in it's new home

Chris